Anatolia se doit de rester au sommet de l’industrie en recherchant et en mettant en œuvre des avancées technologiques de pointe afin d’optimiser les opérations et d’améliorer l’expérience de nos clients. Dans cette optique, Anatolia a collaboré avec différents partenaires technologiques pour atteindre ces objectifs. Des avancées sont en cours dans tous les sites d’Anatolia, y compris ceux de Toronto, Savannah et Izmir. Ce processus de modernisation a commencé dans notre entrepôt de Savannah, en Géorgie, qui a connu d’énormes changements depuis septembre 2022 et dont les rénovations devraient être achevées fin juin 2023. L’utilisation de la robotique figure parmi les solutions que nous avons mises en œuvre pour accélérer notre modernisation technologique.

Commandes entrantes

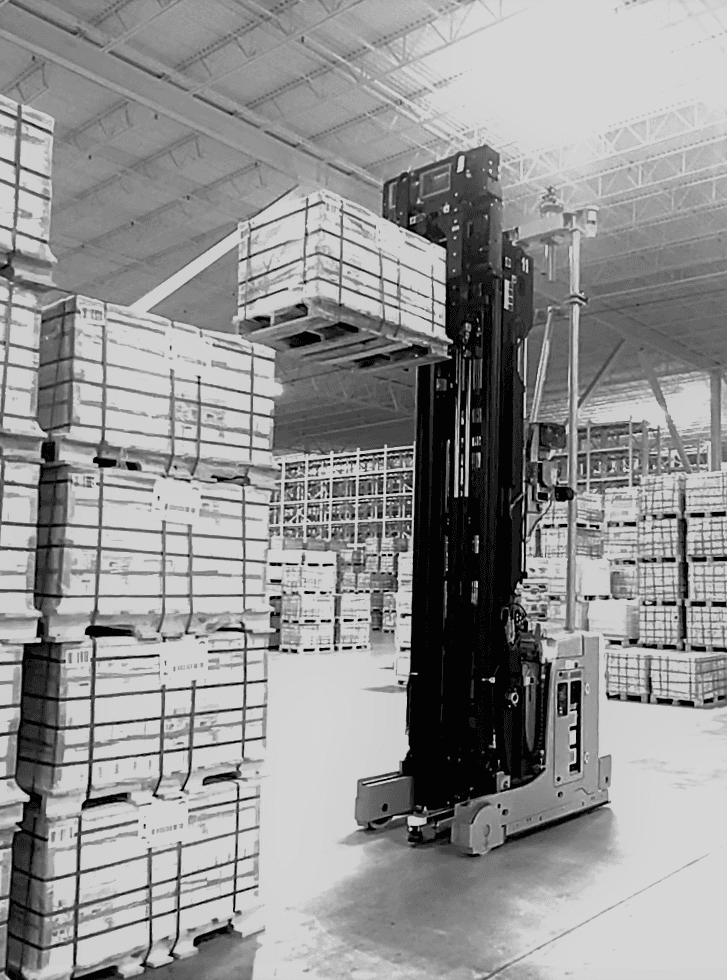

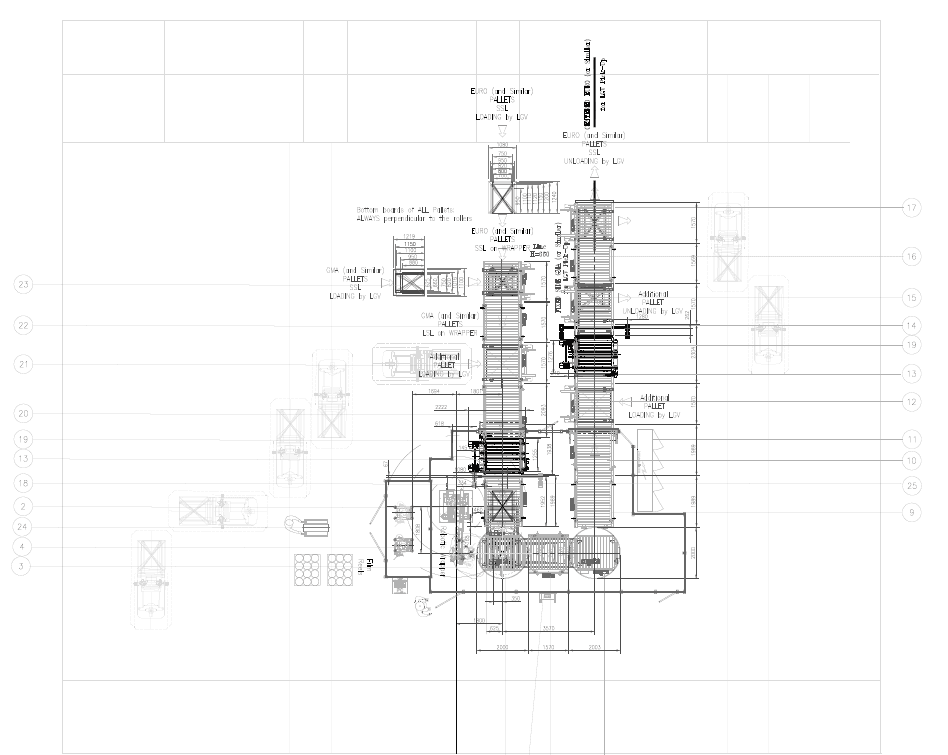

Le nouveau processus automatisé de traitement des commandes entrantes d’Anatolia commence par le placement d’une palette entrante sur un convoyeur à bande ultramoderne qui lit les étiquettes sur la palette et compte les articles pour s’assurer que toutes les pièces sont prises en compte. Ensuite, le système pèse et mesure la palette, vérifie qu’elle n’est pas endommagée par l’humidité et la positionne de manière à ce qu’elle soit prise en charge par un véhicule à guidage laser (VGL). Ce véhicule transportera ensuite la palette de manière autonome jusqu’à l’emplacement correct dans l’entrepôt.

Commandes sortantes

Le nouveau processus automatisé de commande sortante d’Anatolia débute avec la récupération par le VGL de la palette demandée à son emplacement dans l’entrepôt. Il transporte ensuite la palette jusqu’à la zone d’expédition désignée. Si la commande est inférieure à la quantité contenue dans la palette, le VGL dépose la palette sur un autre système de convoyeur qui la lit, la pèse et la déplace vers une zone désignée où elle est fractionnée manuellement et expédiée. Les articles restants sur la palette retournent dans le système pour être lus, pesés et renvoyés à leur place dans l’entrepôt par le VGL.

Unité de stockage vertical pour le prélèvement d’échantillons

L’entrepôt de Savannah abrite désormais une unité de stockage vertical (USV) automatisée pour le prélèvement d’échantillons, qui accueillera une grande variété d’échantillons couramment commandés. Le processus automatisé de sélection des échantillons permettra d’accroître la rapidité et la précision de l’envoi des échantillons aux clients.

Anatolia améliore constamment son service, jour après jour, afin d’optimiser l’efficacité de ses opérations et d’améliorer l’expérience de ses clients. Notre système compte actuellement 45 000 palettes codées, et il en reste 50 000 à intégrer dans le système. Anatolia est actuellement en mesure d’expédier 8 000 palettes par semaine. Les nouveaux processus mis en œuvre devraient permettre d’augmenter la capacité de 275 %, pour atteindre 30 000 palettes par semaine. Les nouveaux processus sont évolutifs, et leur capacité continuera d’augmenter au fur et à mesure de la croissance de l’entreprise.