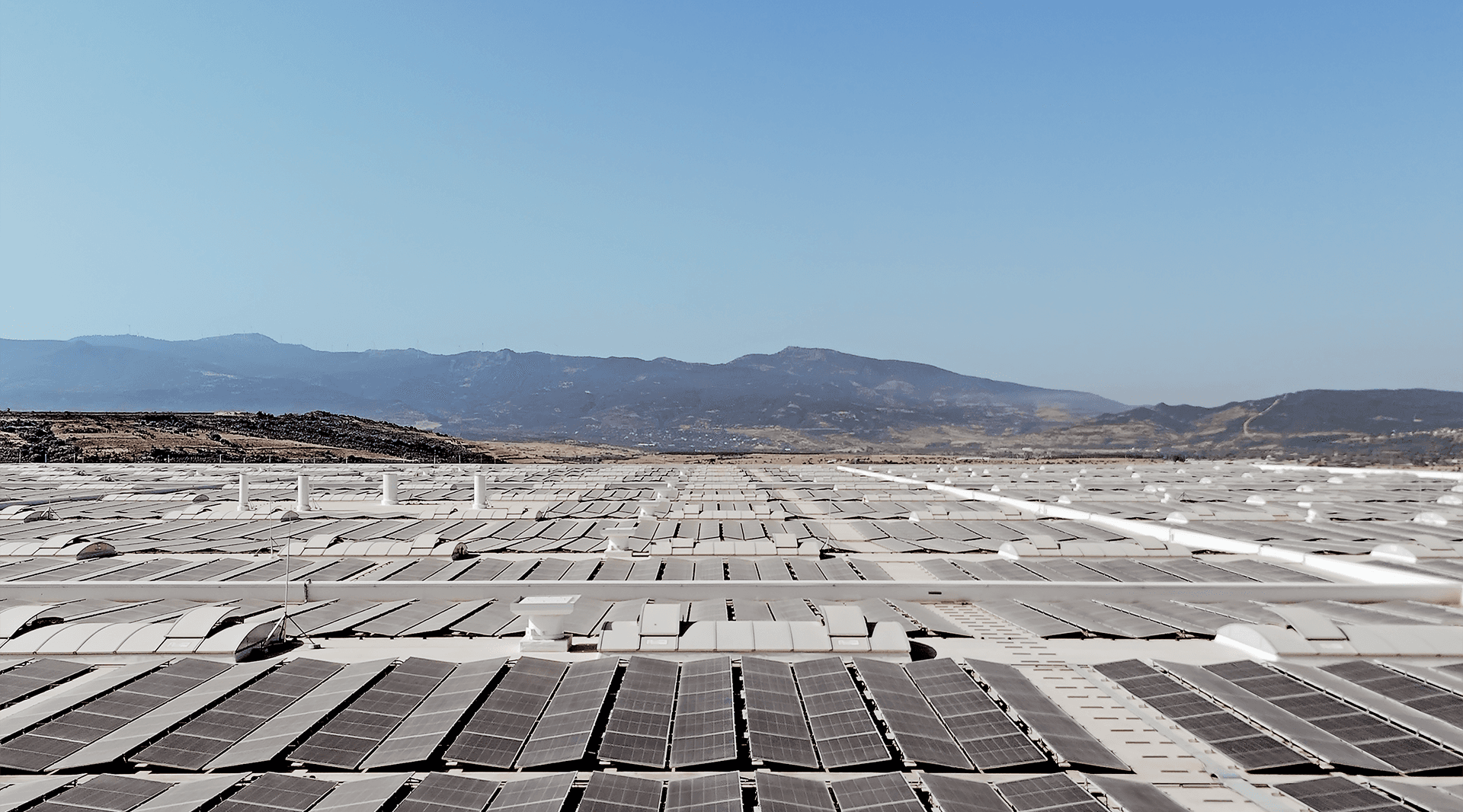

Spanning over 2 million square feet, Anatolia’s cutting-edge facility in İzmir, Turkiye, exemplifies our dedication to innovation and sustainability. It features advanced technology including solar panels that span the entire roof of the facility, a closed-loop indoor water treatment system, a 2,200-ton rainwater collection cistern to ensure exceptional quality and environmental responsibility, automated raw material management, scrap and material recovery and high efficiency press and kiln technology.

Designed to transform manufacturing, the facility combines high efficiency and automation with eco-conscious practices, establishing a new industry benchmark and truly setting Anatolia apart as an industry leader.

Among our many innovative processes, two hallmark practices stand out for their profound impact on our environmental footprint: renewable energy infrastructure and waste reduction systems.

Leading in Energy Efficiency

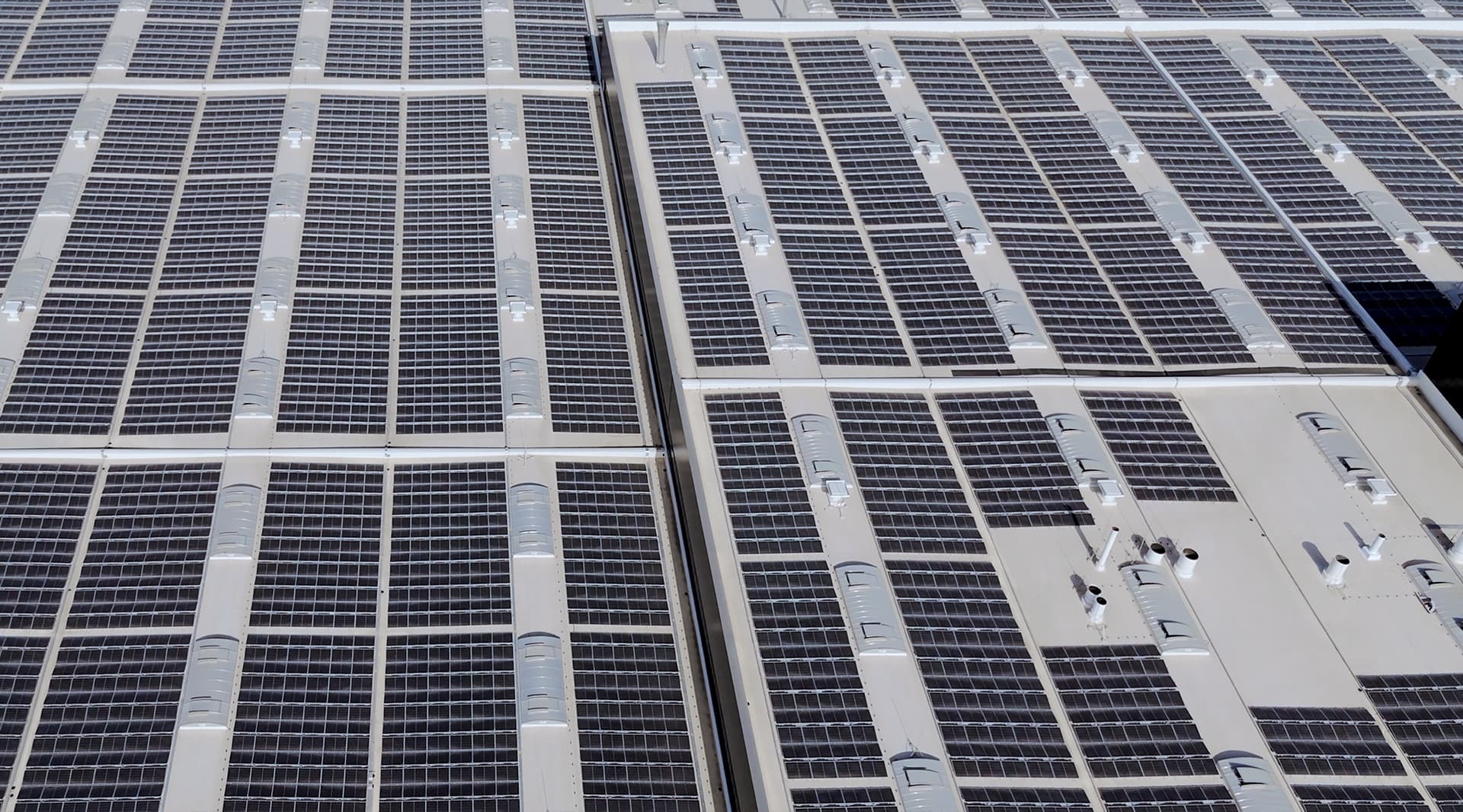

At the heart of our commitment to sustainability is a significant shift towards renewable energy. Anatolia has installed an expansive solar panel network across the entire factory roof generating 21.5 megawatts of solar energy; this transformative initiative allows us to meet a significant percentage of our total electrical energy needs.

Furthermore, it prevents the release of 19,000 tons of carbon emissions into the atmosphere annually, demonstrating our dedication to reducing our environmental footprint on a meaningful scale.

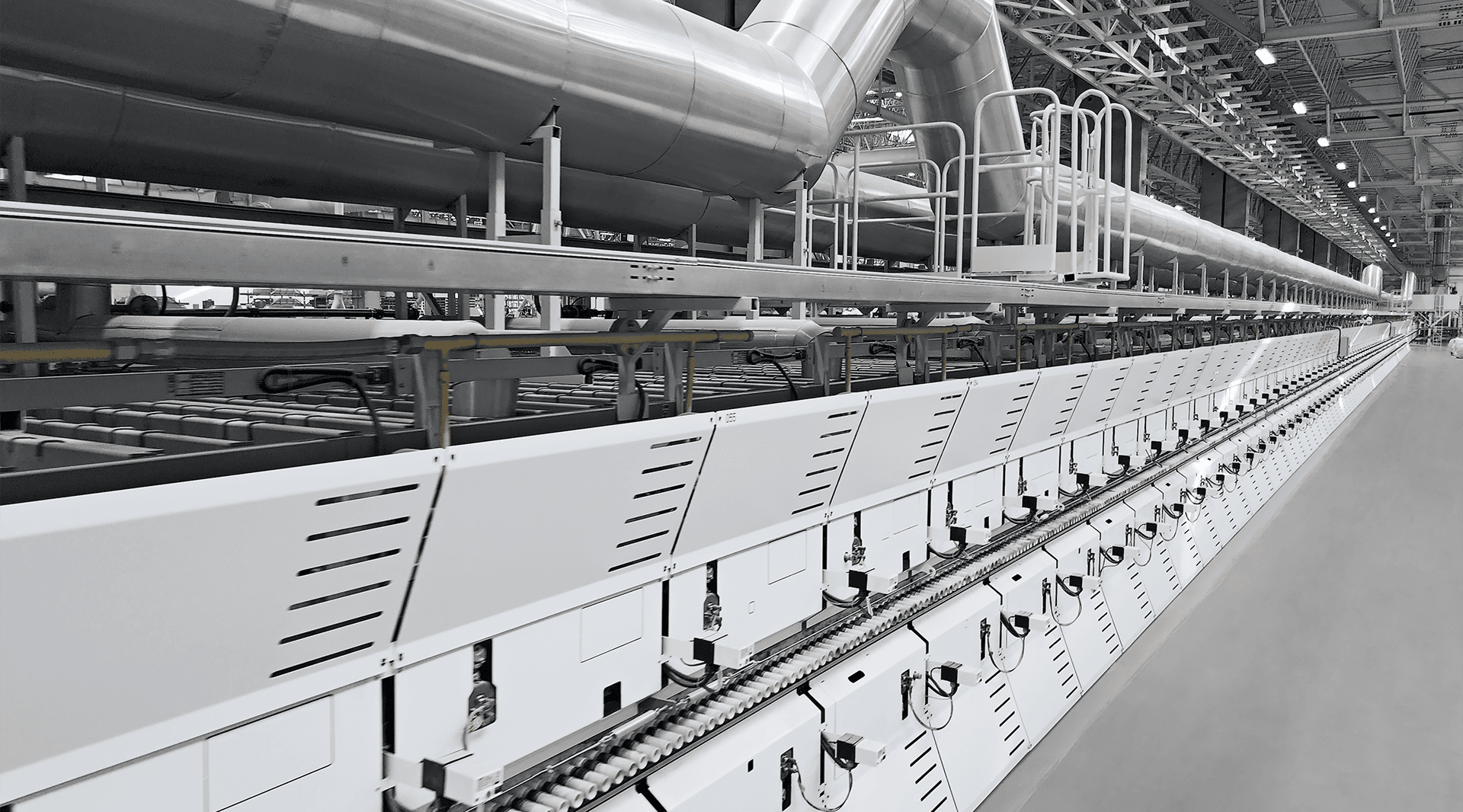

We take a multifaceted approach to achieve our energy efficiency goals which are also reflected in our kiln infrastructure. Each kiln is equipped with an excess heat recovery system. Energy savings from high thermal insulation and effective filtration methods help fulfill Anatolia’s sustainability goals.

Targeting Waste Reduction

Anatolia has an unwavering commitment to achieving zero waste. Our waste management strategy leverages a two-pronged approach, focusing on minimizing waste generation and maximizing recycling.

All waste generated in our factory is separated at its source and either properly disposed of or recycled. Anatolia has the world's first, fully automated material recycling system, which captures all production scrap and debris from air quality filters, dosing it back into production. This approach enables us to increase the use of recycled materials in our manufacturing processes. Furthermore, we’ve identified and eliminated inessential processes, such as doing away with non-recyclable plastic packaging by implementing an automatic ink filling system.

We always seek to innovate and streamline our waste management systems. Our line-up includes a scrap recovery system to reuse unfired and fired scrap products in addition to a waste compactor unit to recycle materials such as cardboard boxes, wooden pallet scraps, and nylon. We aspire to be an industry leader for design excellence and production expertise.

Wise Water Usage

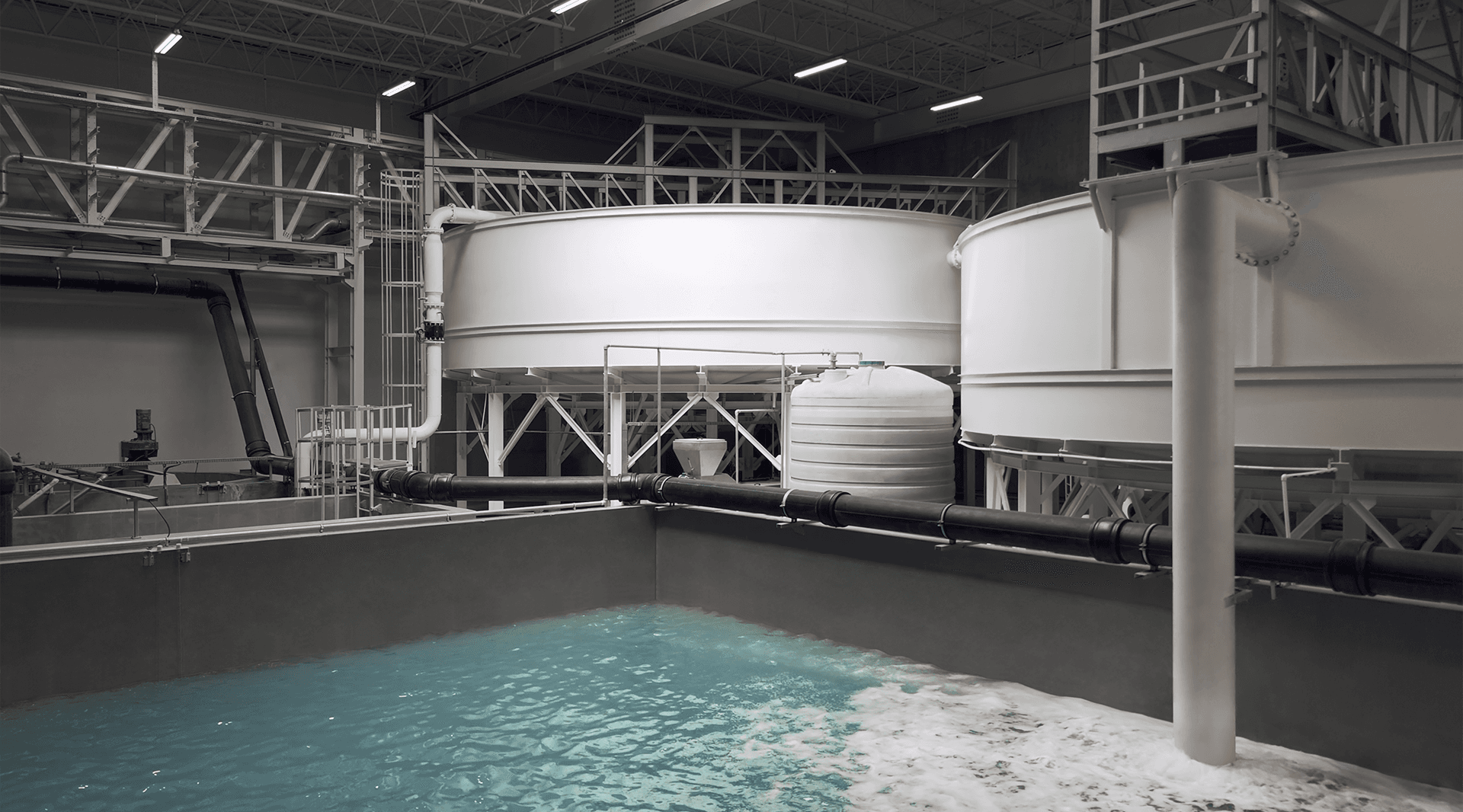

Enhanced waste reduction goes hand in hand with judicious water usage. Of all the water used across our production and operations, 90% comes from recycled sources within our facility. In addition to our treatment plant, another cornerstone of our water consumption reduction strategy is the development of an extensive rainwater collection system. The system comprises a 30,000 m2 catchment basin located across our roof, which subsequently feeds into a 2200-ton underground reservoir. This collected rainwater supports our fire systems, reservoir water needs, and landscape irrigation, contributing to our overall water conservation efforts.

To ensure our water management is both efficient and sustainable, we have established a state-of-the-art closed-loop indoor water treatment plant that reduces evaporation into the environment and increases recycling capture rate.

These advanced approaches drastically reduce our reliance on fresh water and municipal water sources, ensuring we make the most out of every drop while working toward our long-term goal of sustainable resource management.

Sustainability isn’t just a catchphrase. It’s part of our mission at Anatolia. Since our founding, we have set strict standards for ourselves in minimizing environmental impacts, fostering sustainable relationships with the community, and promoting ethical business practices. The design features and production strategies outlined above represent our steadfast commitment to sustainability. Each initiative addresses critical aspects of energy efficiency, water conservation, and waste reduction, enabling Anatolia to make substantial strides in reducing our environmental footprint.

Our pursuit of innovation is woven into our DNA, driving us to continually streamline and improve our business practices, from production to environmental stewardship, to offer the highest-quality products on the market.

As we look to the future, Anatolia remains dedicated to pushing the boundaries of sustainable manufacturing. With every innovation, we continue to lead the industry by example—where efficiency, quality, and environmental responsibility converge. Our journey is far from over, and we’re committed to creating a lasting, positive impact on both our industry and the environment.

From solar panels, indoor water treatment and rain water collection, to automated raw material management, scrap and material recovery, every step in our process reflects our commitment to excellence and environmental responsibility. Stay tuned for what lies ahead as we continue to push the boundaries of design and craftsmanship, shaping the surfaces of tomorrow.