Anatolia is committed to staying at the forefront of the industry by seeking out and implementing cutting-edge technological advancements to optimize operations and enhance our customer experience. With this objective in mind, Anatolia has collaborated with various technology partners to see these goals realized. Advancements are underway in all Anatolia locations, including Toronto, Savannah, and Izmir locations. This journey to technological advancement began in Savannah, Georgia, with our warehouse experiencing tremendous change beginning in September 2022, with renovations on track for completion in late June 2023. One of the ways in which we have made moves to increase technological advancements is through the use of robotics.

Inbound Orders

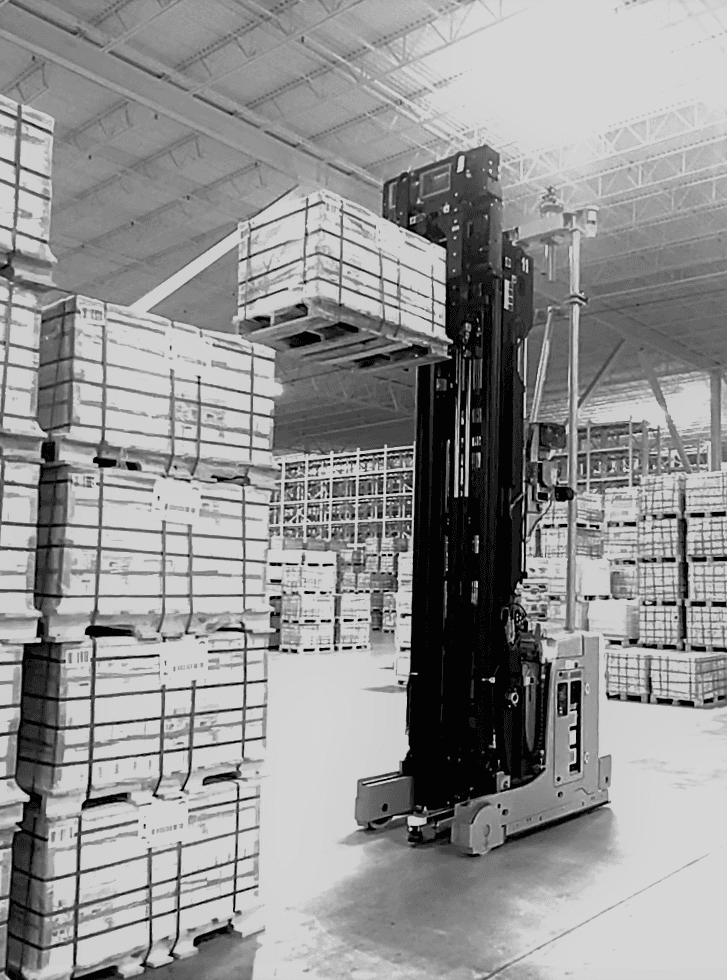

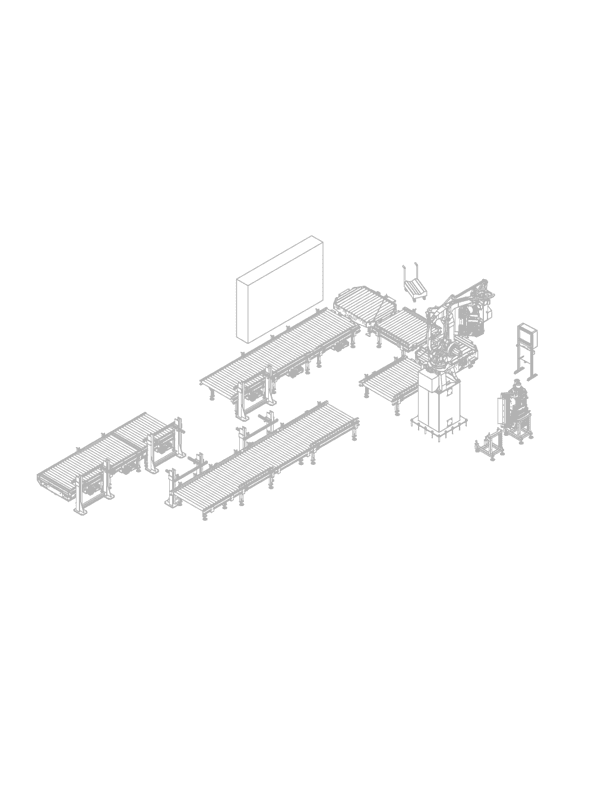

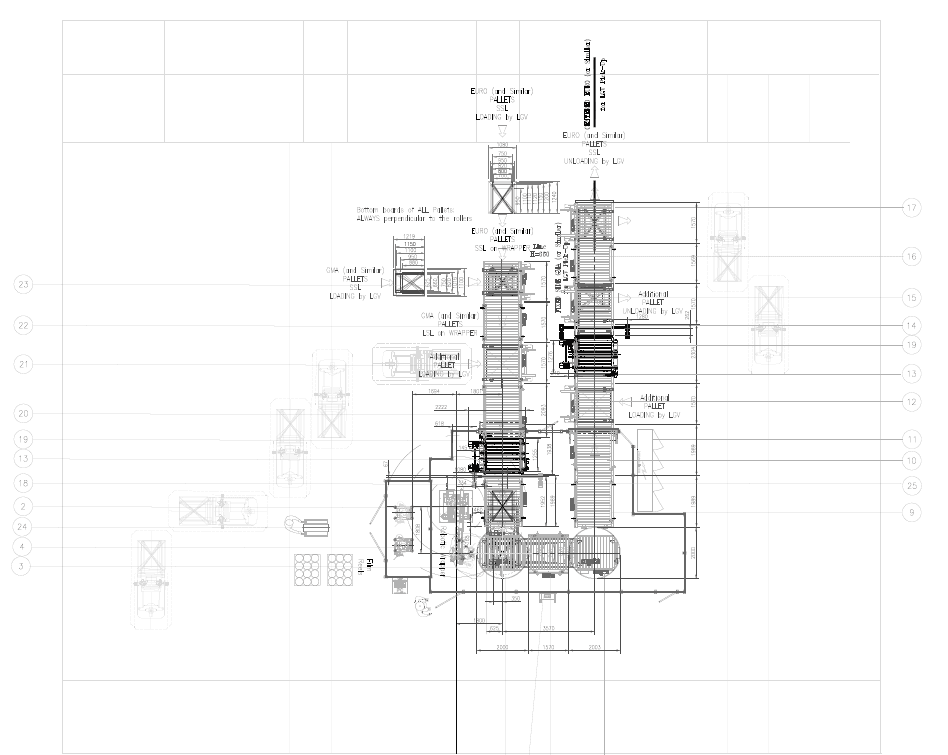

Anatolia's new automated inbound order process begins with the placement of an inbound pallet on a high-tech conveyer belt system that scans the labels on the pallet and counts the items to ensure all pieces are accounted for. Next, the system weighs and measures the pallet, checks for any humidity or moisture damage, and positions the pallet to be picked up by a Laser Guided Vehicle (LGV). This LGV will then autonomously transport the pallet to the correct location in the warehouse.

Outbound Orders

Anatolia's new automated outbound order process begins with the LGV retrieving the requested pallet from its location in the warehouse. It will then transport the pallet to the designated shipping area. If the pallet being picked has been ordered in a quantity less than what is contained in the pallet, the LGV will deposit the pallet on a different conveyor belt system that will scan, weigh and move the pallet to a designated area where the pallet will be manually broken down and shipped. The remaining items on the pallet will return to the process to be scanned, weighed, and returned to its place in the warehouse via the LGV.

Sample-Picking Vertical Storage Unit

The Savannah warehouse also now contains an automated sample-picking Vertical Storage Unit (VSU) that will contain a wide variety of commonly ordered samples. The automated process in which the samples will be selected will ensure the increased speed and accuracy of samples being sent to customers.

Anatolia is constantly making improvements to our service day-by-day to optimize the efficiency of our operations and to enhance customer experience. There are currently 45,000 coded pallets in the system, with 50,000 remaining to be incorporated into the system. With Anatolia’s current ability to ship 8,000 pallets per week, the newly implemented processes are forecasted to increase capacity by 275% to 30,000 pallets per week. The new processes are scalable, with a capacity that will continue to increase as the company continues to experience growth.